Your attic in a Texas summer can reach 150-160°F—that's hot enough to cook food. This superheated air radiates down into living spaces, forcing your AC to work overtime and literally cooking your roof from the inside.

Poor ventilation is one of the most overlooked factors in premature roof failure, excessive energy bills, and indoor comfort problems. Yet most homeowners never think about their attic ventilation until something goes wrong—shingles curling prematurely, ice dams forming (yes, even in Texas), or mold growing in the attic.

Proper roof ventilation is a system, not just a few vents scattered around. Getting it right reduces cooling costs by 10-15%, extends roof lifespan by 5-10 years, prevents moisture damage, and dramatically improves comfort.

This comprehensive guide covers everything Texas homeowners need to know: why ventilation matters specifically in our extreme climate, how much ventilation you actually need (calculated for your home), types of vents and which work best, installation considerations, and how to tell if your current system is failing. Schedule a professional inspection to have your ventilation system evaluated.

Why Ventilation Matters in Texas Heat

The Physics of Hot Attics

Radiant Heat Transfer:

- Sun heats roof surface → 160-180°F

- Heat transfers through shingles → 150-160°F attic

- Heat radiates down into home → 85-95°F ceiling

- AC struggles to maintain → 75°F indoor temp

The Problem: Your AC is trying to cool your home while your attic acts like a giant radiator heating it from above. It's like trying to keep an ice chest cold while sitting on a hot stove.

The Solution: Proper ventilation removes hot air as fast as it accumulates, keeping attic temps within 20-30°F of outdoor temp instead of 60-80°F above.

The Cost of Poor Ventilation

1. Energy Bills Skyrocket

Poorly Ventilated Attic:

- Attic temp: 150-160°F

- Heat transfer to home: Significant

- AC runtime: +30-50% vs properly ventilated

- Monthly cooling: $250-$400 (summer)

Properly Ventilated Attic:

- Attic temp: 110-120°F

- Heat transfer: Reduced by 40-60%

- AC runtime: Normal

- Monthly cooling: $170-$250 (summer)

Annual Savings: $500-$1,200 per year

2. Premature Roof Failure

Heat Damage to Shingles:

- Designed for surface temps up to 160°F

- Attic heat attacks from below

- Combined front-and-back heat exceeds tolerance

- Accelerates aging by 30-50%

Poor Ventilation:

- Roof lifespan: 15-18 years (vs 25-30 rated)

- Early granule loss

- Curling and brittleness

- Warranty potentially voided

Proper Ventilation:

- Full rated lifespan: 25-30 years

- Even aging

- Warranty protected

- Saves $12,000-$18,000 in early replacement

3. Moisture Problems

Even in dry Texas, moisture accumulates:

Sources:

- Bathroom exhaust (if improperly vented)

- Cooking steam rising

- Laundry dryer venting

- Human respiration (family of 4 = 3-4 gallons/day)

Without Ventilation:

- Moisture condenses on cold surfaces (winter)

- Mold and mildew growth

- Wood rot in roof decking

- Insulation degradation

- Health hazards

With Ventilation:

- Moisture expelled before condensing

- Dry attic year-round

- Structural integrity maintained

4. Comfort Issues

Second-Floor Bedrooms:

- Poor ventilation → unbearably hot

- AC can't keep up

- Sleep quality suffers

- Rooms farthest from AC worst

Proper Ventilation:

- Reduced radiant heat

- Comfortable temperatures

- Even cooling throughout home

Texas-Specific Ventilation Challenges

Extreme Heat (7+ Months/Year):

- Longer cooling season than most US regions

- Attics stay hot March-October

- Ventilation critical for 8 months

Hail and Wind:

- Ventilation openings must withstand storms

- Improperly rated vents = damage and leaks

- Must meet Texas wind zones

Humidity Variation:

- Coastal: High humidity (mold risk)

- Central: Moderate

- West: Dry (less moisture concern)

Solution: Ventilation system designed for YOUR specific location.

How Much Ventilation Do You Need?

The 1:150 Rule (Building Code Minimum)

Standard Calculation:

Formula: 1 square foot of net free ventilation area per 150 square feet of attic floor space

Example:

- Attic floor: 1,500 sq ft

- Required ventilation: 1,500 ÷ 150 = 10 sq ft

- Split: 5 sq ft intake (soffit) + 5 sq ft exhaust (ridge/gable)

'Net Free Area' = actual opening size after subtracting screen/louvers

The 1:300 Rule (With Vapor Barrier)

If you have:

- Continuous vapor barrier on attic floor

- Well-sealed ceiling penetrations

- Modern insulation with vapor barrier

Formula: 1 square foot per 300 square feet

Same Example:

- Attic floor: 1,500 sq ft

- Required: 1,500 ÷ 300 = 5 sq ft

- Split: 2.5 sq ft intake + 2.5 sq ft exhaust

Most Texas homes use 1:150 rule for safety margin in extreme heat.

Calculate Your Home's Requirements

Step 1: Measure Attic Floor Area

Simple Rectangular Home:

- Length × Width = Attic floor area

- Example: 50 ft × 30 ft = 1,500 sq ft

Complex Roof:

- Divide into rectangles

- Calculate each section

- Add together

Step 2: Calculate Total Ventilation Needed

Attic Floor Area ÷ 150 = Total Sq Ft Needed

Step 3: Split 50/50 Between Intake and Exhaust

- Intake (soffit vents): 50% of total

- Exhaust (ridge/gable/turbine): 50% of total

Example (1,500 sq ft attic):

- Total needed: 10 sq ft

- Intake: 5 sq ft (soffit vents)

- Exhaust: 5 sq ft (ridge vent)

Understanding Net Free Area (NFA)

Not All Vents Are Equal:

Vent Type → Net Free Area:

-

Louvered vent: 50-60% of gross area

- 12'×12' vent = 144 sq in gross

- NFA = 72-86 sq in (50-60%)

-

Screen-only vent: 80-90% of gross area

- Better airflow, less blockage

-

Ridge vent: Typically 18 sq in NFA per linear foot

- Check manufacturer spec

- Quality matters significantly

Always check manufacturer's NFA rating—it's marked on the product.

Austin-Area Specific Recommendations

Standard 2,000 Sq Ft Home:

- Attic floor: ~1,600 sq ft (accounting for walls)

- Minimum ventilation: 10.7 sq ft NFA

- Recommended (Texas heat): 13-15 sq ft NFA (25% above minimum)

Intake:

- Continuous soffit vents: Both sides

- 2-inch strip = ~8-9 sq in NFA per linear foot

- 100 linear feet = ~900 sq in (6.25 sq ft) NFA

Exhaust:

- Ridge vent: 40 feet @ 18 sq in/ft = 720 sq in (5 sq ft) NFA

- Or: 4-5 powered attic fans

- Or: Multiple turbine vents

Texas Best Practice: Err on side of more ventilation. Heat is your enemy.

Types of Exhaust Vents (Top of Roof)

1. Ridge Vents ⭐ BEST FOR MOST HOMES

What They Are:

- Continuous vent along entire roof peak

- Low-profile, barely visible

- Shingles cover vent for aesthetics

- Full-length exhaust

Pros:

✓ Even air distribution (entire attic)

✓ No hot spots

✓ Most effective natural ventilation

✓ Aesthetically invisible

✓ No moving parts (no maintenance)

✓ Works with natural convection

Cons:

❌ Requires continuous ridge (some homes don't have)

❌ Must be properly installed (mistakes common)

❌ Doesn't work with hip roofs (no ridge line)

Net Free Area:

- Quality ridge vent: 18-20 sq in per linear foot

- 40-foot ridge: 720-800 sq in (5-5.5 sq ft) NFA

Cost:

- DIY: $3-$5 per linear foot materials

- Installed: $8-$15 per linear foot

- 40-foot ridge: $320-$600 installed

Best For:

- Homes with continuous ridgeline

- New construction

- Roof replacements

- Gable or A-frame roofs

Recommended Products:

- GAF Cobra Ridge Vent

- CertainTeed ShingleVent II

- Lomanco Ridge Vent

2. Turbine Vents (Whirlybirds)

What They Are:

- Spinning metal vents

- Wind-powered (no electricity)

- Visible on roof

Pros:

✓ No electricity needed

✓ More effective than static vents

✓ Work in light wind

✓ Relatively inexpensive

Cons:

❌ Visible (aesthetic concern)

❌ Moving parts wear out (5-15 year lifespan)

❌ Can be noisy (squeaking common)

❌ Less effective than ridge vents

❌ Require proper placement (multiple needed)

Net Free Area:

- 12-inch turbine: 50-70 sq in NFA

- Need 3-5 for typical home

Cost:

- DIY: $30-$60 each

- Installed: $150-$250 each

- 4 turbines: $600-$1,000 installed

Best For:

- Hip roofs (no ridge option)

- Budget-conscious projects

- Homes with good wind exposure

3. Powered Attic Fans (PAFs)

What They Are:

- Electric-powered exhaust fans

- Thermostat-controlled

- High airflow capacity

Pros:

✓ Powerful exhaust (1,000-1,600 CFM)

✓ Thermostat controlled (automated)

✓ Effective in still air

✓ Quick temperature reduction

Cons:

❌ Electricity cost ($5-$15/month)

❌ Maintenance required (motor, bearings)

❌ Can create negative pressure (pulls AC air into attic)

❌ Noise (40-60 dB)

❌ May not be code-compliant (some jurisdictions)

Net Free Area:

- Not applicable (powered, not passive)

- Airflow: 1,000-1,600 CFM typical

Cost:

- Unit: $100-$300

- Installed: $400-$800

- Operating: $60-$180/year

Best For:

- Homes with inadequate natural ventilation

- As supplement (not primary)

- Temporary solution

Controversy: Many building scientists recommend AGAINST powered attic fans due to negative pressure issues. Passive systems preferred.

4. Solar-Powered Attic Fans

What They Are:

- Fan powered by solar panel

- No electrical connection

- Thermostat-controlled

Pros:

✓ No operating cost

✓ Environmentally friendly

✓ No wiring needed

✓ Works when sun shining (peak heat)

Cons:

❌ High upfront cost ($400-$800)

❌ Same negative pressure concerns as PAFs

❌ Less powerful than electric (typically)

❌ Panel can fail or get dirty

Cost:

- Unit: $300-$600

- Installed: $600-$1,200

- Operating: $0

Best For:

- Remote locations

- Off-grid homes

- Environmental preference

5. Gable Vents (Passive)

What They Are:

- Vents on end walls (gable ends)

- Triangular or rectangular

- Passive airflow

Pros:

✓ Inexpensive

✓ Easy to install

✓ No roof penetration

Cons:

❌ Cross-ventilation only (not whole attic)

❌ Creates dead air zones

❌ Less effective than ridge vents

❌ Wind direction dependent

Net Free Area:

- 12'×18' vent: 100-120 sq in NFA

Cost:

- DIY: $15-$40 each

- Installed: $100-$200 each

Best For:

- Supplement to other systems

- Historic homes (aesthetic match)

- Budget constraints

Exhaust Vent Comparison

| Type | Effectiveness | Cost | Aesthetics | Maintenance | Best Use | |------|---------------|------|------------|-------------|----------| | Ridge Vent | ⭐⭐⭐⭐⭐ | $$$ | Excellent | None | Primary - Most homes | | Turbine | ⭐⭐⭐ | $$ | Fair | Medium | Hip roofs | | Powered Fan | ⭐⭐⭐⭐ | $$$$ | Fair | High | Supplement only | | Solar Fan | ⭐⭐⭐ | $$$$ | Fair | Medium | Off-grid | | Gable Vent | ⭐⭐ | $ | Good | None | Supplement |

Types of Intake Vents (Soffits/Eaves)

Intake is EQUALLY important as exhaust. Many homes have adequate exhaust but insufficient intake—system won't work.

1. Continuous Soffit Vents ⭐ BEST OPTION

What They Are:

- Perforated strip running entire soffit length

- Installed during siding/soffit work

- Nearly invisible

Pros:

✓ Even air distribution

✓ No dead zones

✓ Maximum intake area

✓ Aesthetically clean

✓ No maintenance

Cons:

❌ Requires soffit replacement (if retrofitting)

❌ More expensive upfront

❌ Must ensure not blocked by insulation

Net Free Area:

- 2-inch continuous: 8-9 sq in per linear foot

- 16-inch on-center perforated: 6-8 sq in per linear foot

Cost:

- Continuous strip: $2-$4 per linear foot

- Installed (with soffit): $6-$12 per linear foot

Best For:

- New construction

- Soffit replacement projects

- Optimal ventilation

2. Individual Soffit Vents

What They Are:

- Circular or rectangular vents

- Spaced every 3-4 feet

- Retrofit-friendly

Pros:

✓ Easy retrofit (cut holes, install)

✓ Inexpensive

✓ DIY-friendly

✓ No soffit replacement

Cons:

❌ Less total area than continuous

❌ More visible

❌ Labor-intensive (many small holes)

❌ Risk of improper spacing

Net Free Area:

- 4-inch round: 8-10 sq in each

- 8'×16' rectangle: 60-80 sq in each

Cost:

- Vents: $2-$8 each

- Installed: $15-$30 each

Best For:

- Retrofit projects

- Budget constraints

- DIY installation

3. Drip Edge Vents

What They Are:

- Ventilation strip at roof edge

- Replaces standard drip edge

- Slim profile

Pros:

✓ Works where no soffit exists

✓ Good for tight eaves

✓ Replaces existing drip edge

Cons:

❌ Lower NFA than soffit vents

❌ Requires roof edge work

❌ Not suitable as sole intake

Best For:

- Homes without soffits

- Supplement to other intake

Critical: Prevent Insulation Blocking

Common Problem:

- Blown-in insulation blocks soffit vents

- Reduces intake by 50-100%

- System fails

Solutions:

- Baffles/chutes: Cardboard or foam channels

- Install between rafters

- Keep 2-inch air channel clear

- $1-$3 each, every rafter bay

Without baffles, ventilation system is 50% effective at best.

Balanced Ventilation: The Key to Success

Why Balance Matters

Unbalanced System Problems:

Too Much Exhaust, Insufficient Intake:

- Creates negative pressure

- Pulls conditioned air from home into attic

- Increases energy bills

- Defeats purpose

Too Much Intake, Insufficient Exhaust:

- Hot air can't escape

- Attic overheats

- Minimal benefit

Proper Balance (50/50):

- Natural airflow established

- Cool air enters at soffit

- Hot air exits at ridge

- Continuous circulation

- Maximum efficiency

The Stack Effect

How Natural Ventilation Works:

- Hot air rises (physics)

- Exits through ridge vents (top)

- Creates slight negative pressure

- Draws cool air in through soffits (bottom)

- Cycle repeats continuously

This is passive, automatic, and costs nothing to operate.

Requirements for Stack Effect:

✓ Adequate intake (soffit)

✓ Adequate exhaust (ridge)

✓ Clear path between (no obstructions)

✓ Balanced 50/50 ratio

Measuring Your System

DIY Assessment:

Step 1: Count Existing Vents

- Note all exhaust vents (type, size)

- Note all intake vents

- Record locations

Step 2: Calculate NFA

- Look up manufacturer specs (or estimate)

- Multiply by number of vents

- Total intake NFA vs exhaust NFA

Step 3: Compare to Requirements

- Calculate needed (attic sq ft ÷ 150)

- Is actual close to needed?

- Is intake = exhaust?

Step 4: Assess Balance

- Intake ≈ Exhaust? Good.

- Intake < Exhaust? Add intake.

- Exhaust < Intake? Add exhaust.

Installation Considerations

DIY vs Professional Installation

DIY-Friendly Projects:

- Adding individual soffit vents

- Installing gable vents

- Replacing turbine vents

- Installing baffles in attic

Requires Professional:

- Ridge vent installation (roof work)

- Powered attic fans (electrical)

- Large-scale soffit replacement

- Structural modifications

Common Installation Mistakes

Mistake #1: Insulation Blocking Soffit Vents

- Solution: Install baffles/chutes, every rafter

Mistake #2: Mixing Vent Types Improperly

- Problem: Ridge vent + gable vents = short-circuit (air out gables, not through attic)

- Solution: Choose one exhaust type (ridge preferred)

Mistake #3: Inadequate Intake

- Problem: Focus on exhaust, forget intake

- Solution: 50/50 balance always

Mistake #4: Power Vents with Insufficient Intake

- Problem: Creates negative pressure

- Solution: Ensure intake exceeds exhaust draw

Mistake #5: Sealing Attic Too Much

- Problem: Air-sealing penetrations is good, but blocking soffit vents is bad

- Solution: Seal ceiling penetrations, never block vents

Ridge Vent Installation (Overview)

Professional Job—Don't DIY unless experienced:

Steps:

- Cut 2-inch strip along ridge (specialized saw)

- Install ridge vent product

- Cover with ridge cap shingles

- Seal properly to prevent leaks

Critical Details:

- Must cut through sheathing, not just shingles

- Proper nailing pattern essential

- Quality ridge vent product matters

- Weatherproofing critical

Cost: $8-$15 per linear foot installed

Payback: Energy savings + roof longevity = 3-7 years

Retrofit vs New Construction

New Construction:

- Plan ventilation from start

- Continuous soffit vents built-in

- Ridge vent standard

- Optimal system easy

Retrofit:

- Work with existing structure

- May require creative solutions

- Soffit access may be difficult

- Cost-benefit analysis needed

Retrofit Priority:

- Ensure soffit intake adequate (baffles + add vents)

- Upgrade exhaust (ridge vent if possible)

- Balance system

- Monitor results

Ventilation for Different Roof Types

Gable Roofs ⭐ EASIEST

Best System:

- Ridge vent (exhaust)

- Continuous soffit vents (intake)

- Natural balance

Alternative:

- Gable vents (exhaust) if no ridge

- Soffit vents (intake)

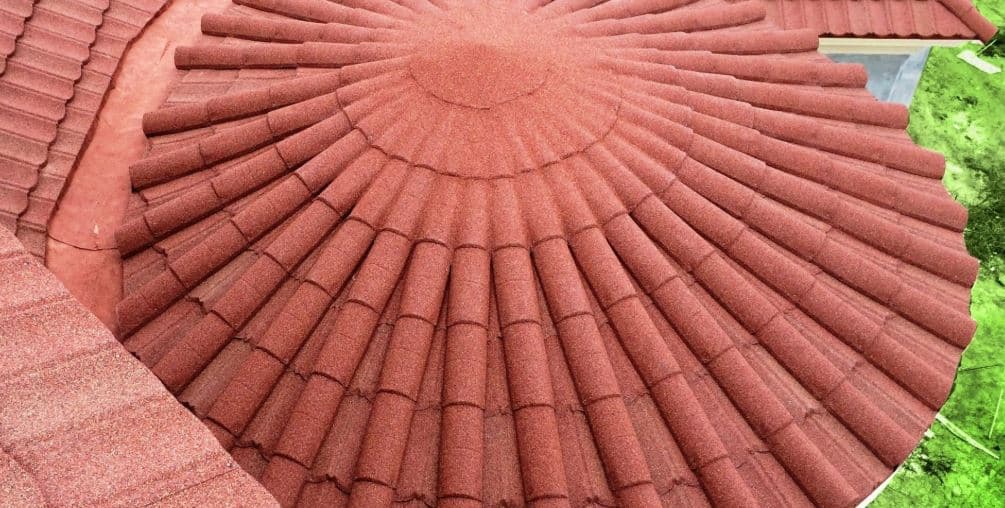

Hip Roofs

Challenge: No ridge line (or very short)

Best System:

- Multiple turbine vents or box vents

- Continuous soffit vents

- Calculate NFA carefully

Alternative:

- Powered attic fan (sized properly)

- Ensure sufficient intake

Flat or Low-Slope Roofs

Challenge: No natural stack effect

Best System:

- Mushroom vents or low-profile box vents

- Soffit intake (if present)

- May need powered assistance

Commercial:

- Mechanical ventilation often required

Complex Roofs

Multiple Ridges/Valleys:

- Ridge vent on each section

- Ensure intake under each section

- Avoid dead zones

Additions/Dormers:

- Ventilate each attic space separately

- Don't assume connected

- May need multiple systems

Moisture Control Benefits

Ventilation isn't just about heat—it's about moisture too.

Summer Moisture

Sources:

- AC condensation

- Bathroom/kitchen exhaust leaks

- Humid outdoor air

Problem:

- Humid air in hot attic condenses on cool AC ducts

- Drips onto insulation

- Mold growth

Solution:

- Ventilation removes humid air

- Keeps dew point below surface temps

- Dry attic year-round

Winter Moisture (Yes, in Texas)

Sources:

- Interior humidity rises into attic

- Cooking, showers, breathing

Problem:

- Cold attic surfaces (winter nights 30-40°F)

- Warm humid air condenses

- Wood rot, mold

Solution:

- Ventilation removes moisture before condensing

- Keeps attic temp close to outdoor

- Prevents condensation

Coastal Texas Considerations

High Humidity Year-Round:

- Greater moisture risk

- Mold more common

- Ventilation absolutely critical

Recommendations:

- 1:150 ratio minimum (not 1:300)

- Consider dehumidification

- Regular attic inspections

Energy Savings Breakdown

Cooling Cost Reduction

Typical Austin Home (2,000 sq ft):

Before Proper Ventilation:

- Attic temp: 150°F

- Ceiling temp: 95°F

- AC runtime: 18-20 hrs/day

- Monthly cost (July-Aug): $350-$450

After Proper Ventilation:

- Attic temp: 115°F

- Ceiling temp: 85°F

- AC runtime: 12-14 hrs/day

- Monthly cost (July-Aug): $240-$300

Monthly Savings: $100-$150 (summer)

Annual Savings: $600-$900

ROI Calculation

Ventilation Upgrade Cost:

- Ridge vent (40 ft): $600

- Additional soffit vents: $300

- Baffles: $150

- Total: $1,050

Annual Savings: $750

ROI: 1.4 years

Plus:

- Extended roof life: 5-10 years (value: $12,000-$18,000)

- Improved comfort: Priceless

- Reduced HVAC wear: $500-$1,000 saved

Total value: $13,000-$20,000 over roof life

Signs Your Ventilation is Inadequate

Check for These Warning Signs

Summer Indicators:

❌ Attic excessively hot (150°F+ with outdoor 95°F)

❌ Second floor rooms always hot

❌ AC runs constantly

❌ High electricity bills

❌ Shingles curling prematurely

Winter Indicators:

❌ Moisture on attic surfaces

❌ Mold or mildew smell

❌ Water stains on ceiling

❌ Frost on nails in attic (rare but possible)

Year-Round Indicators:

❌ Roof aging faster than expected

❌ Ice dams forming (in rare freezes)

❌ Rusted nails in attic

❌ Deteriorated insulation

❌ Visible insulation blocking soffit vents

DIY Attic Temperature Test

Hot Summer Day (95°F+ outside):

- Measure outdoor temp (shade)

- Enter attic at 3-4 PM (hottest time)

- Measure attic temp (center of attic)

- Calculate difference

Good Ventilation: Attic temp 20-30°F above outdoor

Acceptable: 30-40°F above

Poor: 50°F+ above

Example:

- Outdoor: 97°F

- Good attic: 117-127°F

- Poor attic: 147-157°F

If attic is 50°F+ above outdoor, ventilation inadequate.

Maintenance and Monitoring

Annual Inspection Checklist

Spring (March-April):

✓ Check all vents clear of debris

✓ Verify soffit vents not blocked (from inside attic)

✓ Ensure baffles still in place

✓ Look for moisture stains

✓ Check turbine vents spinning freely

Fall (October-November):

✓ Clear leaves from soffit vents

✓ Verify exhaust vents clear

✓ Check for wasp nests

✓ Test powered fans (if present)

✓ Inspect attic for moisture issues

Cleaning and Upkeep

Soffit Vents:

- Remove debris with vacuum or brush

- Check for paint blocking perforations

- 10-15 minutes annually

Ridge Vents:

- Visually inspect from ground

- Look for damage or blockage

- Professional inspection every 3-5 years

Turbine Vents:

- Lubricate moving parts annually

- Replace if squeaking or stuck

- Lifespan: 10-15 years

Powered Fans:

- Clean blades annually

- Check thermostat operation

- Replace motor every 10-15 years

Monitor Energy Bills

Track Monthly Usage:

- Note significant increases (may indicate ventilation failure)

- Compare year-over-year

- Summer usage most revealing

If bills suddenly increase:

- Check attic ventilation first

- Verify soffit vents not blocked

- Ensure exhaust vents functioning

- Consider professional assessment

Frequently Asked Questions

Q: Can I have too much ventilation? A: Practically, no. Oversized ventilation doesn't hurt (unlike oversized AC). More airflow = better in Texas heat. Balance intake/exhaust ratio still matters, but erring on side of more ventilation is fine.

Q: Should I close attic vents in winter? A: NO. Never close attic vents. Moisture control critical year-round. Even in Texas winters, need ventilation to prevent condensation. Unvented attics require completely different design.

Q: Do radiant barriers replace the need for ventilation? A: No. Radiant barriers reduce radiant heat transfer but don't remove hot air. Need both: radiant barrier + ventilation = maximum effectiveness. Ventilation is non-negotiable.

Q: My AC ducts are in the attic. Does ventilation help? A: Absolutely critical. Cool ducts in 150°F attic lose efficiency. Ventilation reduces attic temp, reducing heat gain to ducts. Can improve AC efficiency 15-20%.

Q: Can I mix ridge vents and gable vents? A: Not recommended. Creates short-circuit—air exits gable vents instead of traveling through attic. Choose one exhaust type. Ridge vent preferred; if using, block or remove gable vents.

Q: How do I know if my soffit vents are blocked? A: Enter attic during daytime. Look toward soffits—should see daylight through vent openings. If dark, insulation is blocking. Install baffles to clear.

Q: Are powered attic fans worth it? A: Controversial. Some HVAC pros say no due to negative pressure issues. If natural ventilation inadequate and can't be improved, may help. Ensure sufficient intake. Passive systems preferred.

Q: Does spray foam insulation eliminate need for ventilation? A: Closed-cell spray foam against roof deck creates 'unvented attic' system. Requires different approach—no ventilation but properly sealed. Must be designed correctly. Consult professional.

Your Ventilation Upgrade Action Plan

Step 1: Assess Current System (This Week)

Measure Attic Floor:

- Calculate square footage

- Determine ventilation requirement (÷ 150)

Inventory Existing Vents:

- Count exhaust vents (type, size)

- Count intake vents

- Calculate total NFA

Temperature Test:

- Hot afternoon, measure attic temp

- Compare to outdoor temp

-

30°F difference = needs improvement

Step 2: Identify Deficiencies (This Week)

Common Issues:

□ Insufficient exhaust area

□ Insufficient intake area

□ Unbalanced (exhaust ≠ intake)

□ Insulation blocking soffit vents

□ No ridge vent (but have ridge)

□ Turbine vents not spinning

Step 3: Plan Upgrades (Next Week)

Prioritize:

High Priority:

- Install baffles if soffit vents blocked (DIY: $100-$200)

- Add soffit vents if intake insufficient (DIY: $200-$400)

- Upgrade exhaust to ridge vent if possible (Pro: $600-$1,000)

Medium Priority: 4. Add turbine vents if ridge vent not option (DIY/Pro: $400-$800) 5. Install gable vents as supplement (DIY: $100-$300)

Get Quotes:

- Ridge vent installation

- Soffit vent installation (if complex)

- Compare DIY vs professional cost

Step 4: Execute (Next Month)

DIY Projects:

- Install baffles (weekend project)

- Add individual soffit vents (weekend)

- Install gable vents (weekend)

Professional Projects:

- Ridge vent installation (1-2 days)

- Continuous soffit vent installation (1-2 days)

Step 5: Monitor Results (Summer)

After Upgrade:

- Repeat temperature test

- Compare attic temps before/after

- Monitor energy bills

- Note comfort improvement

Expect:

- 30-40°F reduction in attic temp

- 10-20% reduction in cooling bills

- Noticeably cooler upstairs rooms

Get Professional Ventilation Assessment

Ripple Roofing & Construction provides comprehensive attic ventilation evaluations and upgrades.

Schedule Ventilation Assessment:

📞 Call (512) 763-5277

📧 Email info@rippleroofs.com

🌐 Visit rippleroofs.com/estimate

Our Ventilation Service Includes:

- Complete attic and ventilation assessment

- NFA calculations for your specific home

- Temperature testing and analysis

- Ridge vent installation

- Soffit vent upgrades

- Balanced system design

Serving Round Rock, Austin, Georgetown, Cedar Park, Pflugerville, Leander, and all Central Texas.

Beat the Texas heat. Proper ventilation = lower bills, longer roof life, better comfort.